Achieving laminar flow over an aircraft has been called the holy grail of aerodynamics — a goal engineers have been chasing for nearly 90 years. Why? Because laminar-flow control offers fuel efficiency, range, and endurance improvements unmatched by any other single aeronautical technology.

For transport aircraft, laminar flow could reduce fuel burn by as much as 30%. Whenever it has been successfully applied, even partially, the results have been remarkable.

But if the rewards are so great, why don’t all modern aircraft use laminar flow? The answer lies in the enormous challenges of maintaining it — challenges that, thanks to modern materials and advanced engineering, are closer than ever to being overcome.

What Is Laminar Flow?

To understand laminar flow, we first need to understand drag — the force that resists an aircraft’s forward motion.

- Induced drag: A by-product of lift.

- Parasitic drag: Caused by skin friction — the “stickiness” of air against the aircraft surface.

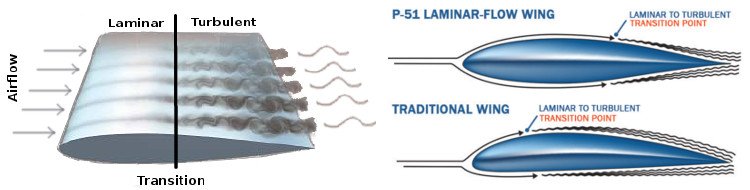

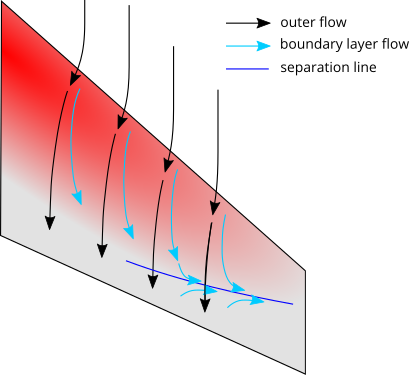

The biggest contributor to total drag in smooth aircraft bodies is parasitic drag, which depends on the boundary layer: the thin sheet of air flowing right next to the aircraft surface.

- If the boundary layer remains laminar (smooth and orderly), drag stays low.

- If it transitions to turbulent, skin friction — and therefore drag — increases dramatically.

This makes laminar flow incredibly valuable. An “ideal” wing would keep laminar flow across its entire chord length, but even maintaining it across 35% of the chord produces measurable benefits.

Early Successes: From WWII to NASA

The story of laminar flow in aviation begins in World War II.

- B-24 Liberator: Accidentally achieved laminar flow over its wings, improving performance.

- P-51 Mustang: First deliberate attempt to use laminar flow. Even partial success on the wing’s outer portion gave it a decisive edge in range and efficiency.

After the war, NASA took the torch forward:

- X-21 (1960s): Demonstrated laminar boundary layers on swept wings — a monumental achievement.

- F-16XL: Modified fighter fitted with a titanium glove of laser-cut suction holes, proving laminar flow control could even work at supersonic speeds.

Swept wings make laminar flow harder to achieve due to crossflow instabilities.

Natural vs. Active Control

Maintaining laminar flow is notoriously difficult. Even a raindrop, insect splat, or speck of dust can trigger turbulence. Surface smoothness and airfoil shape matter enormously.

Natural Laminar Flow (NLF)

- Relies on ultra-smooth surfaces and favorable wing shapes.

- Simpler and cheaper but very sensitive to imperfections.

Laminar Flow Control (LFC)

- Uses suction through microscopic holes to remove unstable boundary layer air.

- Cooling techniques can also help stabilize flow.

Hybrid Laminar Flow Control (HLFC)

- Combines NLF at the leading edge with LFC further back.

- Tested successfully on the NASA X-21 and later experimental aircraft.

Modern Applications

Laminar flow never disappeared — it has quietly shaped several revolutionary aircraft:

- HondaJet HA420: Uses NLF for outstanding fuel efficiency in its class.

- Airbus A340 & A320 prototypes: Research suggests even limited laminar flow could reduce drag by 8% and fuel burn by 5%.

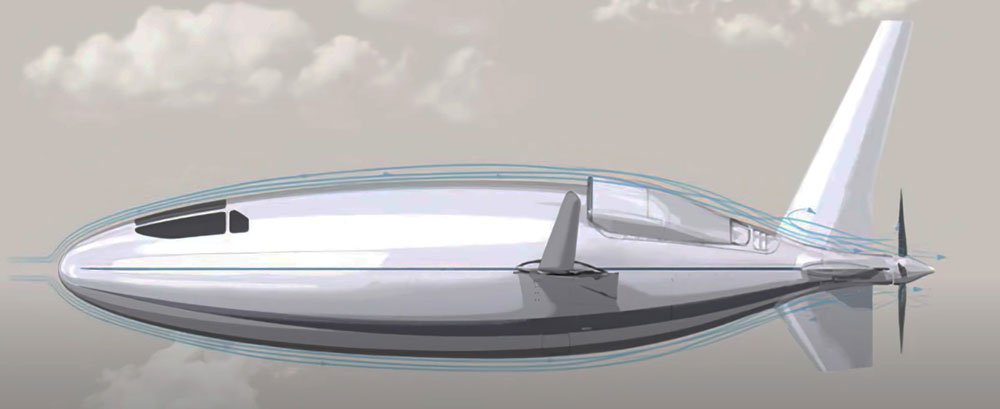

- Celera 500L: The most radical design yet. With laminar flow over its entire fuselage, wings, and tail, it achieves an astounding 59% drag reduction.

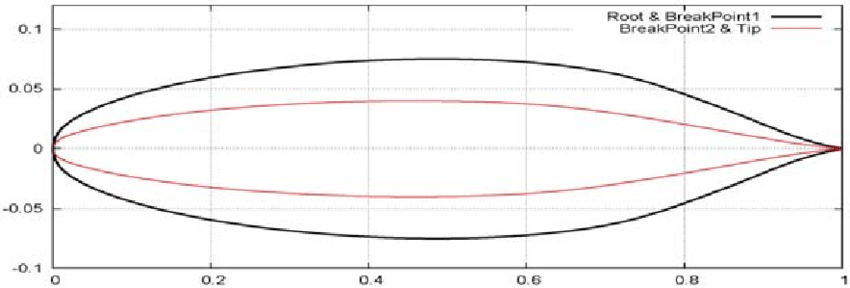

The Celera’s fuselage resembles a laminar-flow-optimized NACA 67-1015 airfoil.

Why the Celera 500L Is Different

NASA studies in the 1980s showed that fuselage drag alone could account for nearly 50% of an aircraft’s total drag. Most laminar-flow efforts focused on wings, leaving this untapped.

The Celera 500L changed that. Otto Aviation designed the entire aircraft around laminar flow principles, giving it the iconic “bullet” shape. The result: unmatched efficiency in the business jet category.

However, scaling up laminar-flow fuselage designs is challenging. As aircraft size increases, so does the Reynolds number — making flows more likely to turn turbulent.

The Future of Laminar Flow

New technologies are making laminar flow practical at last:

- Femtosecond lasers: Can drill ultra-fine suction holes in metal with high precision.

- Hybrid configurations: Like NASA’s Double Bubble D8, which uses engines to ingest and stabilize the boundary layer.

- Drones and next-gen jets: Already experimenting with laminar designs, hinting at radically different aircraft shapes to come.

Laminar flow could even enable:

- Nonstop global flights without refueling.

- 24-hour endurance aircraft, staying aloft continuously.

Conclusion

Laminar flow remains one of aviation’s greatest engineering challenges — fragile, unstable, and unforgiving of imperfection. But when mastered, it offers performance benefits that no other technology can match.

From the Mustang to the Celera, from suction gloves to futuristic “double bubble” concepts, laminar flow is slowly shifting from dream to reality. And when it finally takes hold, the way we build — and fly — aircraft will never be the same.