In recent years, artificial intelligence has revolutionized how we create—from generating realistic conversations with ChatGPT to producing stunning visuals with Midjourney. But what if AI could go beyond the digital realm and help design real-world machines—like aircraft?

That future is already here.

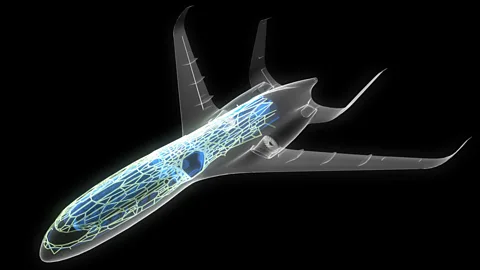

A growing number of engineers are using AI-powered generative design to rethink how we build planes and other complex systems. Coupled with additive manufacturing (also known as 3D printing), this technique is creating radically different shapes and structures—far removed from conventional design templates.

What Is Generative Design?

Generative design is a process where engineers input performance goals and constraints into specialized software. These inputs might include weight limits, spatial boundaries, strength requirements, and load forces. Once the criteria are set, the AI takes over—rapidly generating thousands of design iterations and evaluating their performance.

The result? Optimized designs that often look more like something found in nature than in traditional engineering playbooks.

The role of the human designer shifts dramatically in this process—they become curators, selecting the best solutions from a sea of algorithm-generated possibilities.

A Technology That’s Spreading Fast

Generative design gained public attention in 2018 when Autodesk—a leader in engineering software—demonstrated its capabilities on the BBC. Autodesk began exploring the technology in 2015, initially using it to design a car. Since then, its reach has expanded far beyond the automotive industry.

Today, generative design is being applied in aerospace, industrial machinery, furniture, and even wearable tech. It’s quickly becoming one of the most disruptive technologies in product design.

The Challenges of Manufacturing AI-Generated Designs

Despite its promise, generative design comes with hurdles. The complex, organic shapes it produces are often too intricate for traditional manufacturing. That’s where 3D printing comes in—it’s the only practical way to bring these designs to life.

However, 3D printing remains expensive and slow, especially for mass production. The design process itself is also computationally intensive, relying on cloud computing to crunch millions of equations and simulations.

Transforming Aerospace, One Component at a Time

The aerospace industry is among the biggest adopters of generative design.

Take Airbus, for example. The company used Autodesk’s generative design tools to create a new cabin partition for its A320 aircraft. The final product—nicknamed the bionic partition—features a skeletal design with criss-crossing rods at unconventional angles. It’s 45% lighter, saving about 30 kilograms per aircraft. That seemingly small change could lead to a reduction of 465,000 metric tons of CO₂ emissions annually.

Airbus envisions an entire Bionic Airliner by 2050, where generative design and additive manufacturing work together to minimize weight and maximize efficiency.

Can AI Design an Entire Aircraft?

Designing individual parts is one thing, but can AI design an entire plane?

Researchers at Delft University of Technology in the Netherlands are exploring just that. Their AIDA project uses AI to compare and optimize conceptual aircraft designs. Meanwhile, Germany’s Aerospace Center (DLR) is using AI to fine-tune combat aircraft for specific missions.

Even NASA is on board. For upcoming missions to Jupiter and Saturn’s moons, the space agency used generative design to create lander legs that are 35% lighter than earlier designs.

Organic Designs in Drones and Landing Gear

Generative design is also making waves in the drone world. Quadcopter drones designed through AI exhibit organic forms tailored perfectly to weight and space constraints.

In Greece, a team of students recently reimagined nose landing gear using generative design. The result? A form that looks more like bone or coral than traditional metal assemblies.

The Road Ahead: A Balance of Cost and Innovation

While generative design has clear performance benefits, the economics remain a challenge. The dependency on 3D printing means higher production costs. But if the designs offer enough value—through weight reduction, fuel savings, or enhanced performance—they may well justify the expense.

As we look to the future, the synergy between AI-driven form optimization and emerging propulsion technologies could redefine the very shape of flight.

Final Thoughts

Generative design may still be in its early stages, but its potential is undeniable. With AI as a creative partner, engineers are no longer bound by conventional thinking or manufacturing limitations. From lighter aircraft components to futuristic drones and landers, this technology could quite literally reshape the world around us.