For over a century, the roar of engines and the whir of propellers have defined the sound of flight. But a quieter revolution is brewing—one that may forever change how we design, build, and power aircraft. It’s called fluidics propulsion, and it’s not as new as you might think.

Born from Cold War stealth needs and nurtured in the labs of NASA, fluidics is now gaining momentum, with cutting-edge applications from agencies like DARPA and pioneering startups like Jetoptera. This silent, no-moving-parts technology might just be the future of aviation.

What is Fluidics?

At its core, fluidics is the science of using streams of air or liquid to perform functions traditionally handled by mechanical or electronic parts. Instead of flaps, turbines, or rudders, fluidic systems guide airflow through precisely shaped channels to control and power aircraft.

Imagine steering a plane by precisely blowing air over parts of the wing, or generating thrust without a spinning propeller. That’s the promise of fluidics—lighter, quieter, and potentially more reliable aircraft, with far fewer moving parts to break or wear down.

A Cold War Invention with 21st Century Relevance

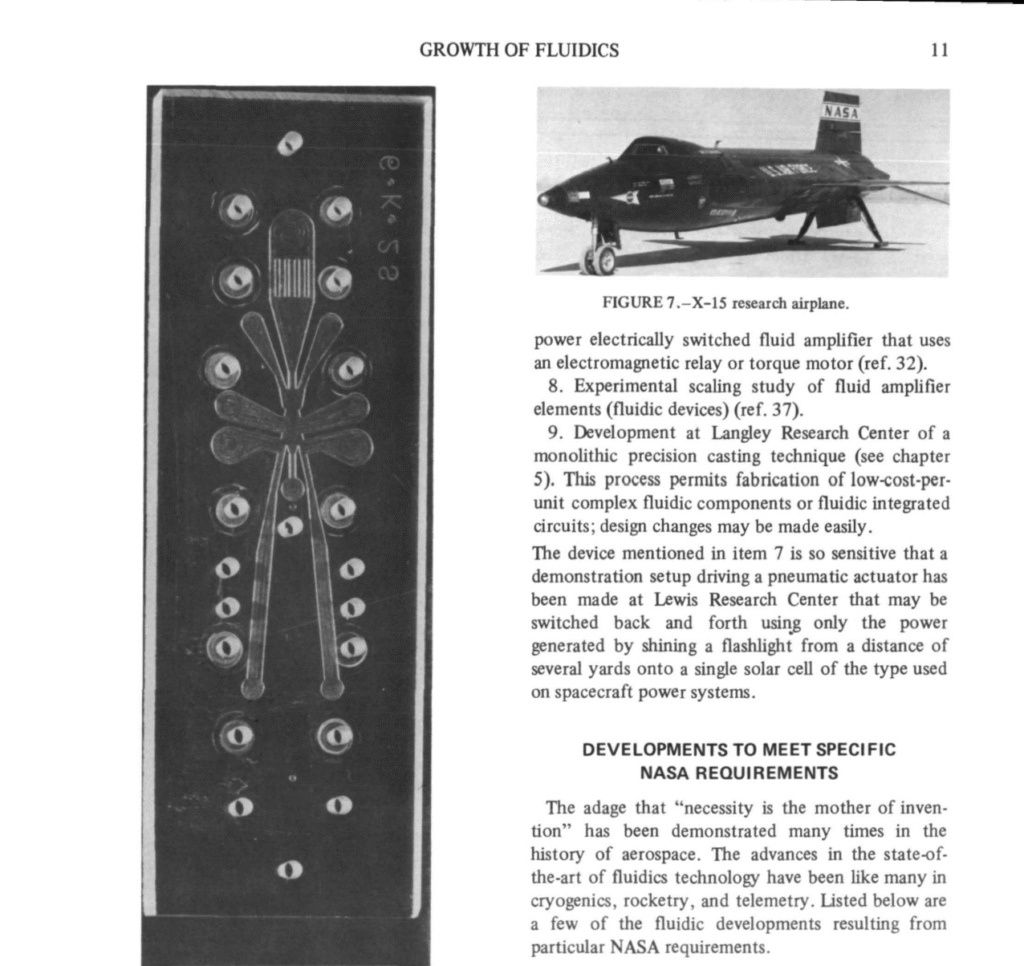

The roots of fluidics stretch back to the 1960s, when NASA began experimenting with air-based control systems to replace heavy mechanical components. The Cold War added urgency to the effort: traditional electronics could be disrupted by electromagnetic pulses (EMPs), while fluidic systems—being entirely mechanical and having no moving parts—were naturally immune.

NASA’s early research focused on internal aircraft systems, but it laid the groundwork for today’s external applications—fluidic flight control and propulsion.

BAE’s “Demon”: A Plane Without Moving Parts

One of the first modern demonstrations of fluidic flight came from BAE Systems, with their experimental UAV known as Demon. Flown successfully in 2010, Demon had no flaps or rudders. Instead, it used jets of air blown over the wings to control flight.

The result? A working aircraft with a smooth, stealth-friendly shape and fewer components to fail. It proved that fluidic control was more than just theoretical—it could actually fly.

DARPA’s CRANE: Redefining Aerodynamics

Taking things a step further, DARPA’s CRANE program (Control of Revolutionary Aircraft with Novel Effectors) aims to eliminate all traditional flight control surfaces. Instead, the aircraft will maneuver using Active Flow Control—precise bursts of air at strategic points to guide airflow and reduce drag.

CRANE isn’t just about making cool tech. It’s about making aircraft more efficient, more agile, and harder to detect. If successful, it could usher in a new design language for military and commercial planes alike.

Jetoptera: Reinventing the Jet Engine

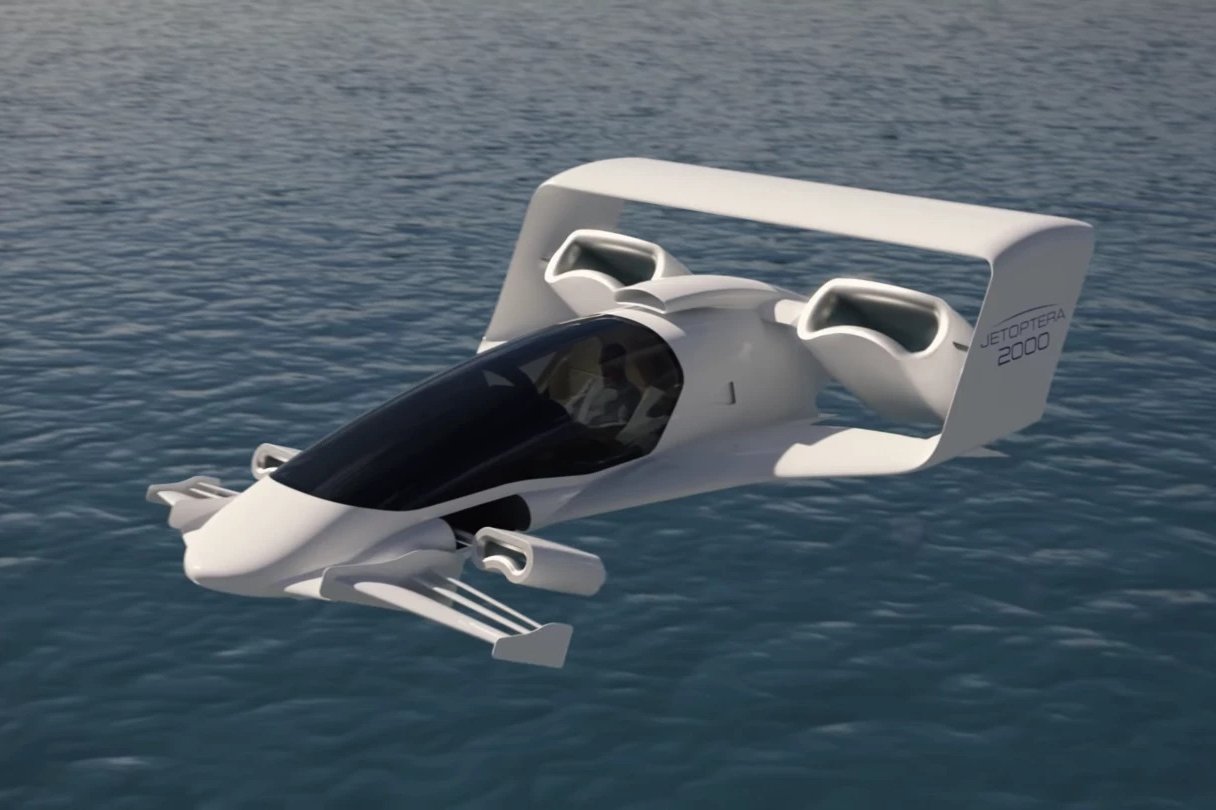

While others focus on control surfaces, Jetoptera is reimagining propulsion itself. Their Fluidic Propulsive System (FPS) replaces traditional jet engines with nozzles that use the Coandă effect—the tendency of air to stick to surfaces—to generate thrust.

This approach allows Jetoptera to entrain more air and boost thrust without compressors or turbines, resulting in a propulsion system that’s quieter, more compact, and mechanically simpler. The potential use cases are exciting: urban air taxis, unmanned drones, and lightweight aircraft designed for tight, noise-sensitive environments.

Global Interest, Including from China

While U.S. and UK projects lead the pack, China has reportedly shown interest in fluidics as well—especially for stealth drones. Without moving parts to reflect radar or make noise, fluidically controlled drones could offer strategic advantages in reconnaissance and electronic warfare.

Though details remain scarce, China’s involvement signals that this is no longer just niche research—fluidics is becoming a globally competitive field.

What’s Holding Fluidics Back?

Despite its promise, fluidic flight faces real engineering challenges. Systems must be robust enough for harsh real-world conditions and seamlessly integrate with digital avionics. Efficiency remains a hurdle—fluidic systems must deliver comparable or better performance than their mechanical counterparts to gain widespread adoption.

But these are solvable problems, and progress is accelerating.

The Bottom Line

The idea of flying a plane without moving parts might sound like science fiction, but it’s quickly becoming science fact. From NASA’s foundational research to BAE’s flight demos, DARPA’s bold designs, and Jetoptera’s propulsion breakthroughs, fluidics is gaining altitude.

It may take a few more years before you’re boarding a commercial plane powered by fluidic systems—but the silent revolution has already begun.

If you’re intrigued by where flight is headed, keep your eyes on fluidics. The future of aviation might not just be electric—it might be almost silent.

References:

NASA’s Fluidic Technology Archives

https://ntrs.nasa.gov/api/citations/19730002533/downloads/19730002533.pdf

BAE systems DEMON

https://www.baesystems.com/en/product/demon-uav–flying-without-flaps

Since your first JetOptera vid I have been inspired.

The ‘real world’ application is my Ultralight that will be 1/2 OV-10 Bronco, and 1/2 YC-14.

Think C-119 Boxcar platform, YC-14 top of wing thrust nozzle mounting, with OV-10 physique scale as seaplane.

It will only carry two same as the OV-10. The retracts will be where the OV-10 wing stubs are located in traditional sponson style. The canopy will be raised and set back only slightly.

One variant is to maintain the short box wings. The second variant is to have Hurel-Dubois Trusses just at waterline into the wing stub, with Burt Rutan SkiGull glider dimension wings. No, not going to

Our great grandpa Rutan Ski Gull is wonderful, but center spar PBY flying boat wing structure removes any possible fuselage space usage.

I think ‘maybe’ I could haul one 3rd person under the tandem seats to the rear laying down

as ambulatory, but there is not enough room to have a med tech monitoring an

injured passenger.

I will NEVER forget your 1st JetOptera video with amazing simple detailed math education on the principle and how it functioned.

And no, it won’t be all Elec. Will have to be two RC Turbojet to power the compressors feeding the thrust nozzles.

You are a good man.

thanks the inspiration

Thank you so much for your comment. The YC14 struck me too when I first say it in a video taking off on a very short landing strip. Thanks for giving me details about your RC concepts. Hope they work well.

Flying car?